By Juliette Lamoureux

I became part of Wicks’ Lab as lab manager and research assistant last fall. Joining in on June’s course on shock experiments, I was introduced to the basic physics and set-up of dynamic compression experiments and assigned velocimetry and X-ray diffraction data to analyze. Then, in December, I was invited to join an experimental campaign at the University of Rochester Laboratory for Laser Energetics (LLE).

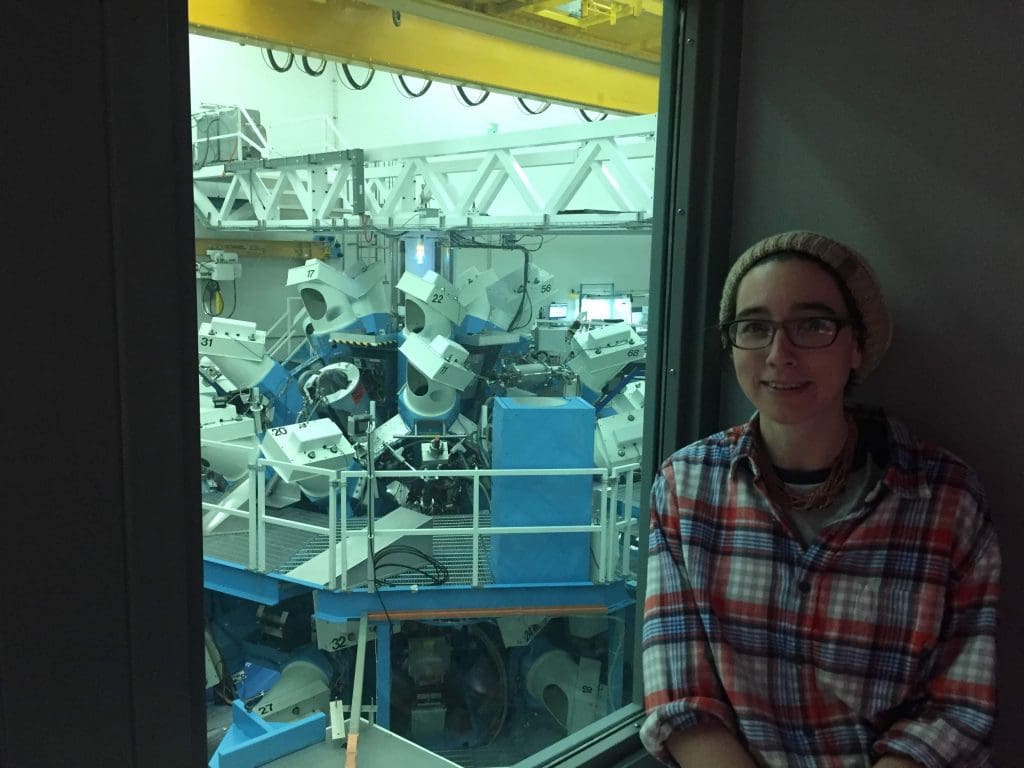

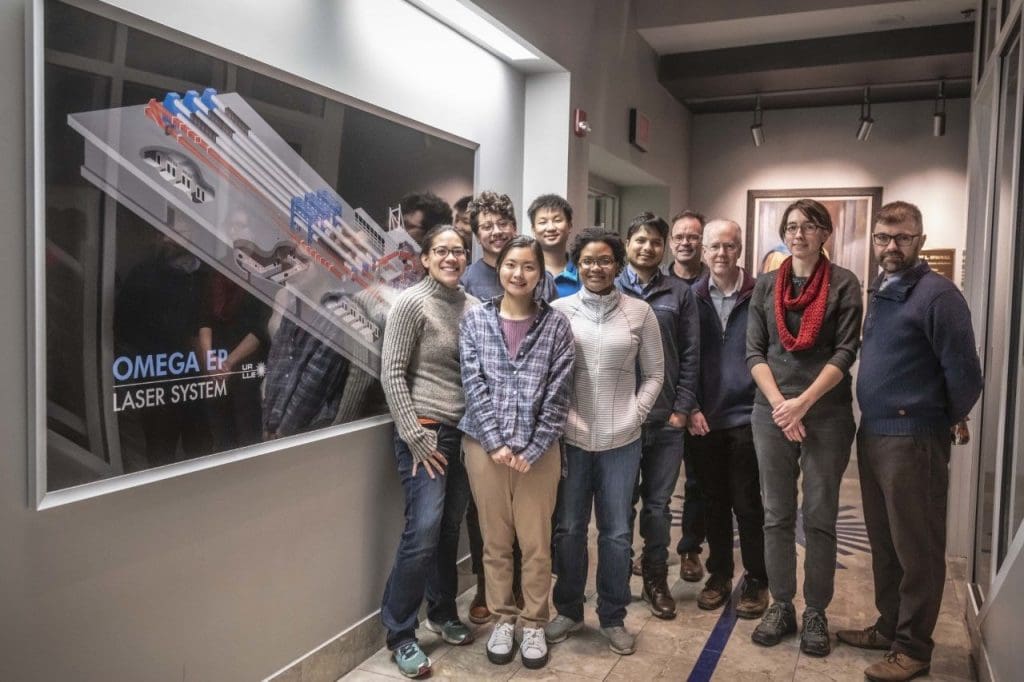

One assigned mission of LLE is to produce experimental scientists in high energy density domains. The atmosphere there exudes commitment to this mission; it was an incredibly welcoming experience to visit as a beginner in the field of mineralogy at extreme conditions. I was encouraged to track down staff scientists and faculty to learn about their projects. It was moving to realize that this was the place where June earned some of her stripes- among many of the same directors, engineers, and scientists that we would be working with for this campaign.

Although I was only picking up some of their terminology, the importance of precise communication between our team and LLE became clear during shot day preparations. Each experiment, or “shot”, of that day had a precise set of specifications for laser energy and configuration based on sample type and objective, and adjustments based on hypothesized problems with data quality from previous campaigns. Shots of the same sample type were spaced out among other types, in the day’s plan. This allowed for the best chance to check for any issues and make adjustments to laser power and timing, and to see if a sample had successfully reached the target pressure. Back-up shots were detailed in the plan, in case a new configuration wasn’t working, or in the case we got what we needed and had time for an extra shot.

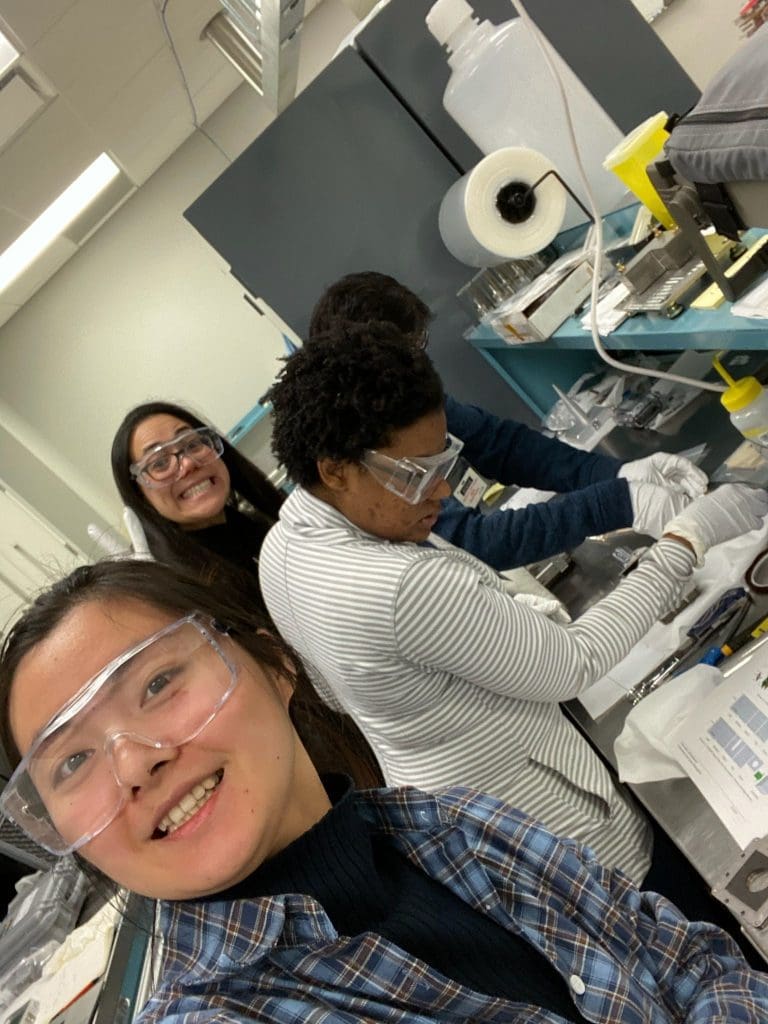

We arrived in Rochester ahead of the assigned shock day to prepare, and to construct the boxes that would hold the image plate that would record the in situ diffraction patterns of our samples under high pressure. My job on shot day would be to graph the laser’s energy levels right after each experiment. There were two groups of lasers: a group of lasers that would generate the shock-inducing pressure wave in the sample, and the lasers that hit our “backlighter” to produce X-rays a few nano seconds later. While others built the X-ray image plate boxes, I practiced downloading and plotting beam profiles, timing myself performing the steps required to produce the graphs and post them to our shared slides.

On shot day we gathered together early in the morning with the engineers, technicians, staff scientists, and shot director. June briefed the room on our scientific objectives and the shot plan for the day for a final once-over of the various configurations planned and their back-ups. The director then received reports from each system’s representative, going around the room, calling on each for their status. Our big day in Rochester was a high intensity experience all the way through. It was an extremely energetic collaboration to support the decisions of the PI with our organizational, analytical, or technical contributions. After each shot- which required set up and take down, collection and posting of data by LLE staff- each of us in the extended Wicks group collected and presented some aspect of the result for discussion and decision making. Tweaks to positioning and laser energies were workshopped and enacted by LLE engineers. In the high-focus efforts of all of us in collaboration, we were driving forward LLE’s mission to conduct research and development in high energy density domains. Together, led by the creative efforts of June and her collaborators, we accessed new areas of high pressure-high temperature, and saw crystal phases for the first time. This work continues to pave the way for new questions and new experiments to be created.

The next day I received a tour from Dave Canning, shot director of the campaign, of the system of lasers that we used for our experiments, as well as another housed by LLE, developed for the purpose of achieving inertial confinement fusion. My tour guide described how a laser beam is generated in the basement level of this enormous space, and then routed and reflected, and split again and again into many beams; then the wavelength is altered. He emphasized how much precision and how many individuals are involved in the production of each nano-seconds long, densely concentrated laser pulse. There’s also a wide variety of research that goes on at the facility, with associated diverse configurations. Considering the complexity and precision required, each experiment is a real accomplishment. But the organization of LLE, founded on principles that informed the Navy’s structure of coordination and execution, has made for a singularly successful institution in this domain. I felt inspired and welcomed to be part of facilitating this science even in my small way.